API Tube Mill

Processing:

Coil Loading → Uncoiling → Cutting & Butt Welding → Accumulating →Fine Leveling → Forming → Welding (Guide Seam, High Frequency Welding, External Burr Removal, Welding Seam Flattening) → Internal Burr Removal → Water Cooling → Online Ultrasonic Testing → NQT Weld Heat Treatment → Air Cooling → Water Cooling → Sizing → Flying Saw Cutting → Roller After Sawing → Off-line Straightening →Hydrostatic Testing → Chamfering → UT Testing of Tube Body →Drift Diameter Inspection → Weighing, Length Measuring and Marking → Packaging

JCOE Processing:

Material prepare→Material feeding → Welding pilot arc board→Milling →Pre-bending →Bending →Pre-welded joint→Inner welding →Outer welding→Remove the arc ignition board→Welding seam UT →Beveling →Visual inspection →Hydro test → Expand diameter→ Welding seam UT→X test→Finishing →Length measuring and weighing →Run out

BER Processing:

Raw material →UT flaw detection of steel plate →Edge milling →Front side butt welding →Turning plate →Reverse side butt welding →Rolling machine feeding →Coil forming →Post bending →Joint weld machine pre-welding →Welding slag removing →Welding arc plate →Inside welding →Slag removing → Outside welding → Press straightening →Weld repairing→Pipe body expanding →Weld repairing →X-ray inspection→Aligning device→Hydrostatic Testing→ End facing and beveling→UT flaw detection of weld→ Finished product inspection→External shot blasting→Internal shot blasting →Storage

Processing:

Coil loading →uncoiling →vertical roller (1)→ straight→levelling→vertical roller(2)→shearing&buttwelding →vertical roller (3) →edge milling 1 →vertical roller(4)→edge milling 2 →cleaning →plate edge derusting →Plate UT→Vertical roller(5)→delivering→ prebending&guide board→forming →internal prewelding →cutting off →pipe outputting→welding arc plate→fine welding→cleaning welding slag→repairing →X-ray testing →trimming&sampling →pipe ends grinding →pipe ends expanding →hydraulic testing →ultrasonic continuous detecting (pipe welding seam and plate) →ultrosonic manually detecting→ beveling&end-facing→ pipe ends X-ray testing →finished products testing → weighting&length measuring →marking →storing(The above-mentioned finishing equipment all meet the requirements of pipe body length ranging from 8 to 18 meters)

Processing:

Pipe Testing →Pipe washing →pipe preheating→ Pipe blasting→Rust remove→Pipe inner blowing→Pipe Treatment →Dust treatment →Pickling →Surface passivation →Industion Heating →FBE Coating →AD Coating →PE Coating→Spraying cooling→Coating Layer testing→ Pipe treatment→Automatic Marking →storing

Processing:

Billet Cutting →Billet Heat Furnace →pipe Piercer→ Rolling →Water descaling→Sizing press reducer→Cooling

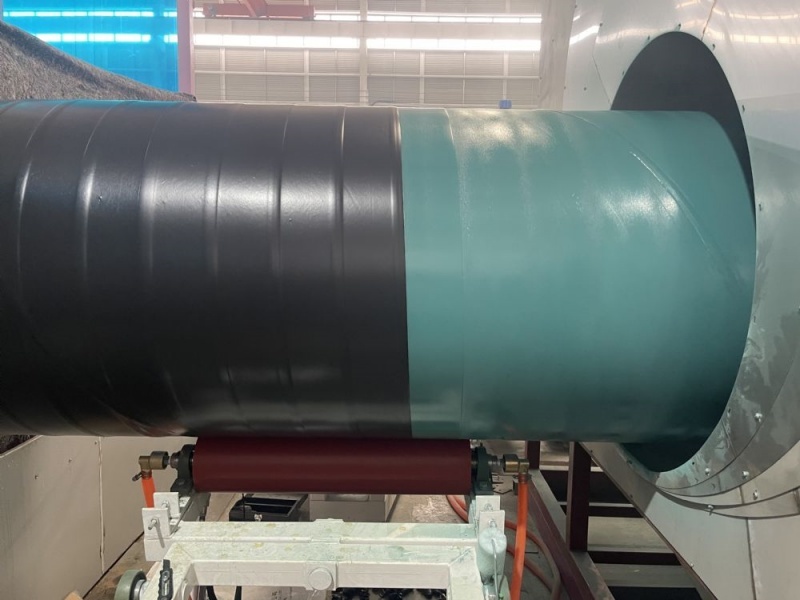

Anti-corrosion Coating Line

3PE Coating, FBE Coating, PE/PP Coating, Liquid Epoxy Coating,Concrete Weight Coating, Isulation Coating, HDPE, Bitumen Coating, Cement Lining

.png)